Screen Printing vs. DTG: Which T-Shirt Printing Method is Right for You?

Key Takeaways:

- Screen printing is ideal for large orders with simple designs, offering cost-effectiveness and durability.

- DTG printing excels in small quantities and complex designs, providing versatility and photographic print capabilities.

- Choosing the right method depends on your specific needs, budget, and design complexity.

I. Introduction

Ever found yourself staring blankly at a screen, desperately needing a stack of custom T-shirts? Maybe you’re kitting out your football team, promoting your band, or just fancy rocking a tee with your own witty slogan. But then the dreaded question hits you: how do I even get these things printed?

Fear not, because in the wild world of custom apparel, two titans reign supreme: screen printing and Direct-to-Garment (DTG) printing. They're the Batman and Superman of T-shirt customization, each with their own strengths and weaknesses. But which one's the right hero for your project?

At Teevolution, your friendly, Manchester-based, family-run T-shirt gurus, we've seen it all. We've wrestled with squeegees, marvelled at DTG detail, and helped countless folks like you bring their tee-tastic visions to life. We're talking top-notch organic cotton tees, powered by renewable energy – because saving the planet and looking good is our jam.

So, grab a brew (we're partial to a good cuppa here in Manchester), settle in, and get ready for a deep dive into the world of T-shirt printing. This article will equip you with the knowledge to choose the best method for your project, ensuring you get the perfect tees, every time. We'll dissect the pros and cons of each method, weigh up the costs, and even throw in a few real-world scenarios to help you make the right call. Let's get cracking!

II. Understanding Screen Printing

The Traditional Approach

Picture this: a stencil, a squeegee, and a whole lotta ink. That's the heart of screen printing, a time-honoured technique that's been around for ages. Here's the lowdown:

- The Stencil: A stencil (or "screen") is created for each colour in your design. Think of it like a carefully cut-out piece of paper, but made of fine mesh.

- The Ink: Ink is then pushed through the stencil onto the T-shirt using a squeegee, one colour at a time.

- The Magic: Each colour is laid down separately, creating the final design layer by layer.

- The Cure: Once printed the garments are passed though a high heat tunnel oven to ensure that the ink cures and bonds to the garments. A process that is essential to ensure longevity, wash-ability and durability.

It's a bit like creating a work of art with a series of carefully crafted stamps. A skilled printer will align each layer of colour accurately, ensuring that the best quality garment is created.

Ideal Uses for Screen Printing

Screen printing is the king of the castle when it comes to:

- Large Quantities: Need 100, 500, or even 1000 tees? Screen printing's your best bet. The more you print, the lower the cost per shirt.

- Simple Designs: Bold, blocky designs with a limited number of colours sing with screen printing. Think logos, slogans, and classic graphics.

Benefits

- Cost-Effective for Bulk: As mentioned, the more you print, the cheaper it gets. This makes it ideal for businesses, events, and organizations needing large quantities.

- Durable Prints: Screen-printed designs are known for their longevity. They can withstand countless washes and still look fresh.

- Vibrant Colours: Screen printing allows for rich, saturated colours that really pop.

Drawbacks

- Setup Costs: Creating those stencils can cost a pretty penny upfront. This makes it less suitable for small, one-off orders.

- Limited Colours: Each colour requires a separate stencil, increasing costs and complexity for designs with lots of hues.

-

Not Ideal for Complex Designs: Think gradients, photographs, or intricate details? Screen printing might struggle to capture the nuances.

III. Exploring Digital Printing (DTG)

The Modern Solution

Enter DTG, the modern marvel that's shaking up the T-shirt printing world. This innovative method is like having a high-tech inkjet printer, but for clothes!

How it Works

- The Digital Design: Your design is uploaded to a computer and sent to the DTG printer.

- The Direct Print: The printer sprays the ink directly onto the fabric, much like printing a document on paper.

- The Magic: No stencils, no fuss, just pure digital wizardry.

Ideal Uses for DTG

DTG shines when you need:

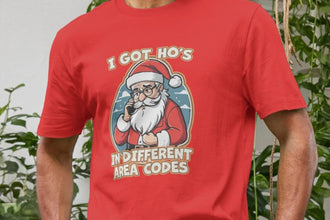

- Small Orders: Whether it’s one single tee or a small batch of 10, DTG is perfect for those limited runs.

- Complex Designs: Photographs, gradients, intricate patterns – DTG can handle it all.

- Personalized Prints: DTG is perfect for printing individual names, numbers, or unique designs on each shirt.

Benefits

- No Minimums: Print as little as one tee without breaking the bank. This is a game-changer for individuals and small businesses.

- Environmentally Better: DTG printing reduces waste by printing on demand. No need to overproduce and end up with unsold stock.

- Photographic Prints Possible: Capture stunning details and vibrant colours with photographic-quality prints.

- Reduces the Need to Hold Stock DTG printing allows the creation of one off's meaning you do not need to hold onto stock of particular designs.

Drawbacks

- Cost Per Shirt Higher: Compared to screen printing, DTG can be more expensive per shirt, especially for larger quantities.

- Design Considerations: Some designs will be more suitable for DTG printing due to their complexity.

IV. Side-by-Side Comparison Table

| Feature | Screen Printing | DTG Printing |

|---|---|---|

| Setup Costs | High | Low |

| Per-Shirt Cost | Low (for bulk) | High (especially for small quantities) |

| Minimum Order Quantity | High | None |

| Image Complexity | Simple | Complex |

| Colour Options | Limited | Virtually unlimited |

| Durability | High | High |

| Fabric Types | Works with many different fabrics | Best on cotton & blends |

V. Real-World Examples

Let's see how these printing methods play out in real-life situations:

- Scenario 1: Business with 500 Employee T-shirts (Screen Printing)

"Our company needed 500 T-shirts with our logo and a simple slogan," says Sarah, the marketing manager. "Screen printing was the obvious choice. The bulk discount saved us a fortune, and the prints look great!"

- Scenario 2: Individual Selling Custom Designs Online (DTG)

"I sell my quirky illustrations on T-shirts," explains Tom, an independent artist. "DTG allows me to print one-off designs on demand, without having to invest in a huge stock. It's perfect for testing new ideas and catering to individual customer requests."

- Scenario 3: Band with a Detailed Album Cover Design (DTG)

"We wanted to print our album cover on T-shirts," says Dave, the lead singer of a local band. "The design was super detailed, with lots of colours and gradients. DTG was the only way to capture the artwork accurately, making our merch look amazing."

VI. Conclusion

So, there you have it, folks! Screen printing and DTG, two fantastic T-shirt printing methods, each with its own strengths and weaknesses. Choosing the right one boils down to understanding your specific needs and budget.

- Got a massive order with a simple design? Screen printing is your trusty steed.

- Need just a few tees with a complex image? DTG will save the day.

At Teevolution, we're all about helping you create T-shirts you'll love, while doing our bit for the planet. We opt for DTG, So you can be rest assured that your tees will be made with vegan-friendly, organic cotton in factories powered by renewable energy. And remember, when you're done with your tee, send it back to us, and we'll give it a new life through our circular fashion program. How cool is that?

So, what are you waiting for? Explore our collection of witty, cheeky designs, or create your own custom masterpiece today! Let's save the planet, one awesome T-shirt at a time. Join the Teevolution!